What is High Density Fiberboard or HDF

We have already mentioned that Step & Wall floors are ready for intensive use. Its high resistance to impact and abrasion makes it a floor suitable even for commercial use.But, if we want to go deeper into the matter, what is the reason?

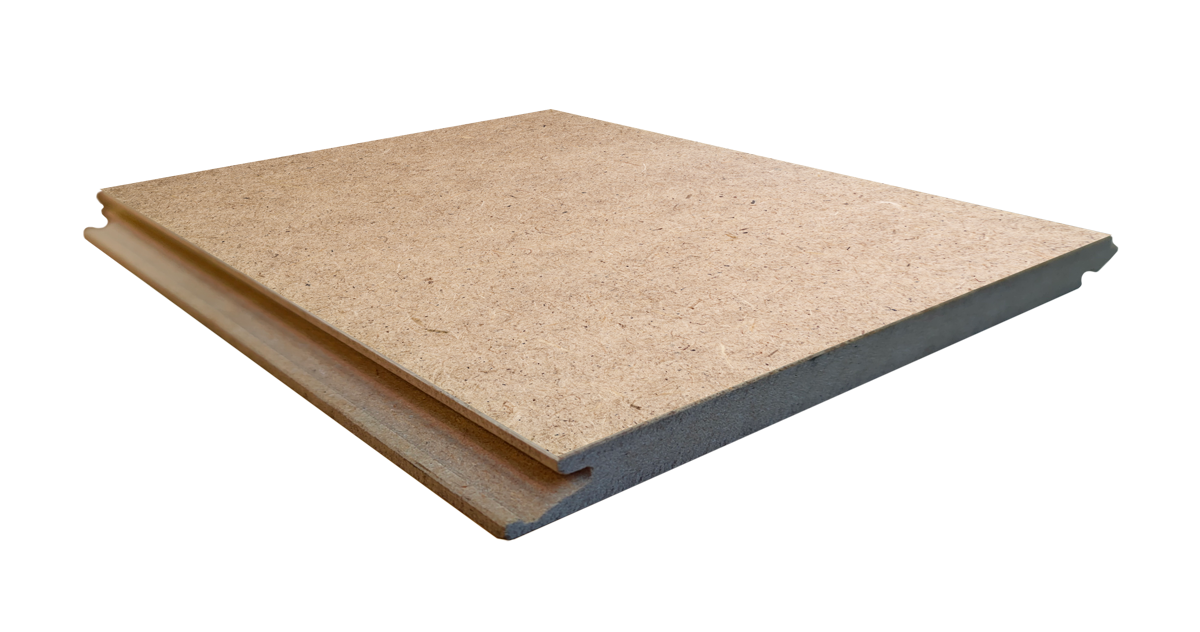

Let's talk about the core of our floors, the basis of the quality of our product. Exactly, it is the High Density Fibreboard or HDF (High Density Fibreboard). We are talking about a technology that by pressing this board gives it much better characteristics than other versions of boards, until then the MDF (Medium Density Fibreboard). Thanks to its high density, we can say that it is much more resistant to impacts and has a greater durability over time.

The density or weight of HDF per cubic meter is between 800-1000 kg/m3 while medium density boards are usually practically in the middle, between 500-600 kg/m3.

By mounting a 0.6 mm wood layer, we are making better use of the high performance provided by this board, resulting in a much more technologically advanced product. We are also being more respectful of the environment and the natural resources available to us.

Advantages of HDF technology

HDF board helps to dampen noise and reduce vibrations due to its greater mass. It will leave a quieter and less noisy environment.

It is compatible with underfloor heating, which will allow us to achieve good energy efficiency and optimize the costs of traditional heating. The HDF middle layer helps the heat to be distributed quickly without causing energy losses.

The water-repellent capacity of the high-density board will provide our floor with greater protection against humidity. HDF boards guarantee a better performance against humidity than solid wood.

Our production processes take advantage of 95% of each log, minimizing wood losses. Our commitment to nature and environmental protection is endorsed by our certificates and seals.

Share in Pinterest